Manufacture of Solid-State Batteries

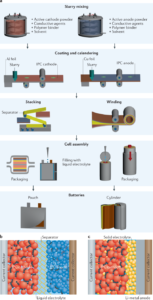

The design and manufacture of solid-state batteries has many complexities. The choice of materials, processing methods and the overall cost of the battery can affect the near-term results in the lab. While a solid-state battery can be cheaper in the short term, the cost of the battery will increase over time as the battery is subjected to more stress. Here are some tips to help you choose the right materials and processes for your needs.

LLZO electrolytes have a low failure rate, which is important for maximizing energy density. However, they are extremely brittle, making them vulnerable to warping or cracking even at high temperatures. Xing and Ceder investigated the effect of the material’s failure rate on its overall cost. They found that a layered electrolyte made up of oxide LLZO was more expensive.

PolyPlus Battery Company is developing a new glassy sulfide solid electrolyte. They are moving from pressing sulfide glasses to a roll-to-roll processing method. They have also developed a liquid electrolyte. This wetting process will prevent the separation of the solid electrolyte from the cathode material. A new generation of solid-state batteries will be able to store more energy than ever before.

Manganese Market Analysis by Martin Kepman CEO of Manganese X Energy Corp

A key innovation in the design and manufacture of solid-state batteries is 3D printing. This new technology can enable greater structural complexity and increased energy density. While 3D printing can be used to manufacture SSEs, it is still a very new field that needs a multidisciplinary team effort to maximize its potential. Furthermore, further experimental and computational studies are needed to understand the composition-structure-property relationships of SSEs. These studies will lead to improved mechanical/chemical stability.

Design and Manufacture of Solid-State Batteries

The development of solid-state batteries is a major challenge. Although they offer the benefits of greater energy density and lower cost, the initial product is still limited by the size of the cell. The first commercially available solid-state battery is a thin-film battery. These cells use layered materials to function as electrodes and electrolytes. Because they are flexible, they can be used to store more energy.

The design and manufacture of solid-state batteries has several advantages over organic liquid electrolytes. They eliminate the risks of explosion and combustion. They have a wide electrochemical window and are resistant to dendrite growth from metallic anodes. They are a superior choice for many applications and have many benefits. These new batteries can be used for a wide range of purposes. A variety of applications can be incorporated in solid-state batteries, from personal electronics to electric vehicles.

Solid-state batteries have a variety of advantages. These batteries can be used in a variety of applications, including portable electronic devices. Despite their unique benefits, these batteries are expensive. They require complex equipment to be manufactured. They may also be difficult to transport, especially in small-scale forms. Therefore, it is essential to ensure that solid-state batteries are compatible with the devices that will be charged. This way, they can be shipped in smaller quantities and avoid any problems.